Advancements in electric vehicle (EV) battery technology are leading the charge when it comes to meeting increasing customer expectations of performance, sustainability and efficiency, and are critical to the wider adoption of electric vehicles across the world.

In this article, we’ll explore how more efficient, cost-effective and sustainable battery technology is set to play a pivotal role in the development of the next generation of electric vehicles.

From the latest developments in innovation and performance to recycling and second-life options, we’ll show just how innovations in electric vehicle batteries have the potential to change the mobility market for good.

Innovation in production: building next-generation batteries

Currently NMC (Nickel Manganese Cobalt) and LFP (Lithium Ferro Phosphate) are the most popular battery types in the market. While NMC batteries are favoured for their higher energy density, allowing for longer driving ranges, many entry-level BEVs utilize LFP batteries due to their cost efficiency and longer life-cycle. The advantages of lithium-ion batteries have carried the EV industry so far, with their high-energy, long cycle life and fast charging properties. But concerns around cost, lifespan, safety and environmental impact of lithium-ion are increasing as the industry expands.

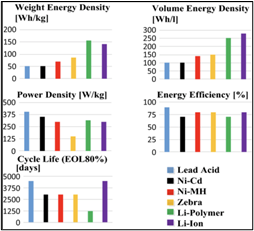

Solid-state, lithium-metal and advanced lithium-ion batteries are some of the options for improved next-generation batteries. Comparing electric vehicle energy performance shows that different types of battery have the capacity for better performance, as you see in this comparison chart.

Source: Electric vehicle batteries comparison | Download Scientific Diagram

Solid state batteries are leading a charge

Solid-state batteries may appear to hold the key to revolutionizing the EV battery industry when compared to lithium-ion.

With a higher energy density and none of the flammable liquid of lithium-ion, they are a safer and more efficient option. By storing more energy in a smaller and lighter package, the design of both batteries and electric vehicles could be improved around them.

A faster charging facility reduces cost and time to charge, which, when coupled with an extended lifespan and better response to temperature extremes, improves overall performance. And the wider range of cheaper and friendlier materials in their construction reduces their environmental impact.

However, there are still challenges to overcome in bringing solid-state batteries to market, and barriers to cross before successful experiments translate into scalable production. Issues with performance under stresses of temperature, altitude and vibration will take time to resolve before wider adoption is scalable and safe.

Although the science is nearly there, and there is large-scale industry investment, timescales for wholesale adoption are expected within the next decade.

Battery chemistry enhancements enabling elemental change

Only better and cheaper battery options will make possible the scale of EV adoption that governments around the world are expecting. As the validation of sold-state batteries as the next big thing takes time to be production-ready, there are battery chemistry enhancements that promise more immediate improvements to battery life and capacity.

- Using silicon rather than traditional graphite anodes reduces weight, increases density and improves performance.

- Lithium sulphur batteries also have higher density, cost less and use more sustainable materials. They do have challenges to resolve with cycle life and stability.

- Sodium is a more readily available alternative to lithium, allowing for more sustainably sourced and cheaper sodium-ion batteries.

- Using lithium metal in batteries could double the energy density and range of electric vehicles.

Winning the production race to meet future demand

30 large-scale manufacturing facilities, or so-called “gigafactories” are planned in Europe alone, set to meet growing demand for EV batteries and to enable economies of scale, all driven by significant investment.

Governments are offering incentives for businesses to invest, offering incentives to attract battery manufacturing and helping offset the large capital investments needed, In December 2023 the European Commission announced a €3 billon investment to boost the EU’s battery manufacturing industry, recognising the importance to the industry of streamlining production processes, reducing costs and meeting growing demand.

Auto manufacturers are forming strategic partnerships and joint ventures with battery manufacturers to secure supply, such as the BMW group and AESC partnership in battery cell production and supply.

Tesla’s first manufacturing location in Europe, Gigafactory Berlin-Brandeburg, promises to create hundreds of thousands of Model Y vehicles and millions of battery cells. Rapid construction techniques mean these facilities can be built very quickly, with Tesla’s Gigafactory Shanghai reportedly being completed in just one year.

Performance improvements: enhancing the EV experience

Addressing common customer concerns and uncertainty about electric vehicles is a core challenge in accelerating EV adoption. Some customers remain to be convinced that EVs can offer a comparable or better experience than conventional internal combustion (ICE) vehicles.

Faster charging is needed to make EVs more practical for everyday use by significantly reducing charging times. To do this, batteries need efficient thermal management so that they don’t overheat, which can reduce battery lifespan and raise safety concerns. New cooling technologies are materials are being developed that address these concerns over rapid charging.

Extreme fast charging (XFC) has been shown to unlock charge transfer limitations on high energy Li-on batteries and increase fast rechargeability.

Battery swapping technology is also being explored where a driver exchanges an empty battery for a fully charged one, although standards in technology for batteries and battery swapping would need to be agreed to enable this.

Extending the driving range of EVs will address the major consumer concern of range anxiety, often cited as a key barrier to EV adoption.

A new battery from 24M claims to significantly enhance longevity and also improve EV resale value. 24M’s batteries use lithium metal instead of lithium-ion, with a higher energy density giving increased storage capacity and longer range. They are expected to be available within the next five years.

Panasonic announced a partnership with Sila Nanotechnologies that would see silicon used in place of graphite, a swap that could be implemented on Panasonic’s existing battery production line as early as 2024.

New battery designs and materials are set to improve the durability and lifespan of EV batteries, while improved thermal management and advanced battery management systems can monitor and optimize battery performance and lifespan.

Closing the loop through sustainability and recycling

Currently, EV batteries are expected to have a life of 15-20 years, or between 100,000-200,000 miles, which look set to outlast the projected 12-year lifespan of the vehicles they power.

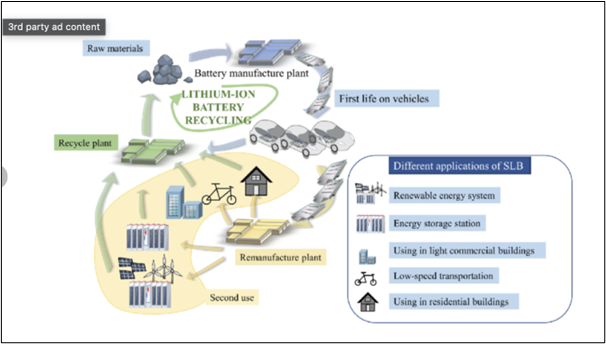

For batteries that do outlive their vehicle lifespan, second-life application options where batteries are repurposed extends their useful life and reduces waste. There are still big challenges ahead when it comes to closing the sustainability loop.

Source: Process illustration of a battery lifecycle with second life | Download Scientific Diagram

When batteries are reduced to 70-80% of their original capacity they are no longer viable for a vehicle but can still be used in stationary energy storage applications, storing energy from renewable sources, where they can help balance the grid and provide back-up power.

Used batteries could also be used for residential energy storage systems for homeowners to store their own excess energy or off-peak electricity. On a larger scale, industrial and commercial energy storage for data centers or factories could help manage peak demand and reduce costs.

Repurposing rather than recycling EV batteries lowers the overall cost of manufacturing and creates possibilities for new revenue opportunities. It’s considered by some as a potentially better option than recycling.

Where repurposing isn’t possible, recycling can reduce environmental impact and reliance on scarce raw materials. Effective recycling would mitigate environmental damage from mining and battery waste, and would address increasing demands of government regulation, such as the Battery Regulation Act in the EU.

As the first generation of electric vehicles reach end of life, organisations like the World Economic Forum are calling for private investment to jumpstart larger-scale lithium battery recycling.

Circular Economy Models creating a more sustainable future

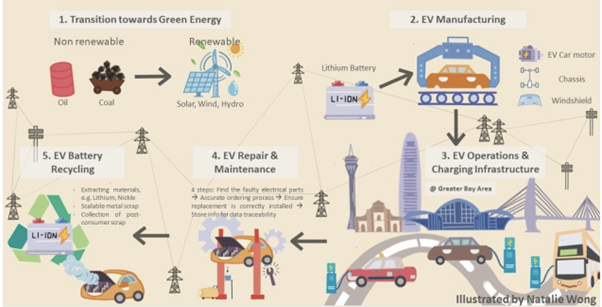

Companies are integrating circular economy principles into their battery designs and production processes, aiming to create a more sustainable and resource-efficient EV industry. It will take some major efforts to re-engineer the supply chain in order to achieve net zero goals.

Source: Supercharging the future - How to rethink EV supply chain to achieve net zero goal?

In designing for recyclability with easier disassembly in mind, using standardized components and avoiding difficult-to-separate adhesives, BMW has developed batteries that can easily be reduced into their raw materials for recycling.

The Battery Passport Initiative from the Global Battery Alliance aims to create a global digital platform for sharing information about EV batteries throughout their lifecycle, with improved labelling and traceability making it easier to identify components for recycling.

Partnerships between auto manufacturers and recycling companies are being designed to ensure closed-loop systems for batteries. Volkswagen has partnered with recycling specialist Redwood Materials to recover materials from end-of-life batteries across VW and Audi.

Nissan and Renault have programs that repurpose EV batteries for residential and commercial energy storage systems, as companies design batteries with second-life applications in mind.

Automated systems that disassemble batteries make the recycling process more efficient and cost-effective. Using robotics and AI to safely and quickly take apart battery packs can save up to 33% compared to the costs of manual recycling.

Estimates claim that there will be $10 billon revenue potential in the circular economy by 2030, and with this in mind investors, regulators and manufacturers are all looking at the opportunities that will bring them commercial and environmental success at the same time.

Where next with EV battery innovation for a brighter future?

It’s critical that innovations in EV battery technology keep up with customer demand for a better-performing, more sustainable future for mobility. From chemistry and design to scalable manufacturing, new battery technologies are breaking down the barriers to wider EV adoption.

Durability and lifespan issues are being resolved and the focus is on circular economy principles to be met is increasing. Battery technologies continue to mature and scale, and have a key role to play in accelerating the transition to electric mobility while contributing to a more sustainable transport sector.