Electrifying fleets is key for reducing their environmental footprint, but it focuses mostly on tailpipe and air pollutants emissions, meaning it’s only one piece of the puzzle.

To fully decarbonize operations, fleet managers need to consider vehicles and their entire lifecycle, complementing the reduction of direct emissions from travel resulting from fleet electrification. How? By reducing resource and energy use and leveraging key principles of the circular economy.

A circular economy approach offers a systems-based solution to the environmental challenges of corporate mobility and isn’t limited to the mere recycling of vehicles’ materials at the end of their useful lifespan.

Instead, it involves all aspects of fleet management, and begins with carefully analyzing users’ effective needs, assessing which vehicles are truly needed, and ensuring fleets and vehicles are right-sized and fit their purpose and use. Once a need is clearly defined, all aspects of a vehicle’s life cycle should be considered – from sourcing to repair, and from reuse to disassembly – all of them also essential for decarbonizing the automotive industry.

In the EU, switching from internal combustion engine (ICE) vehicles to battery-electric vehicles (BEVs) can cut lifecycle emissions by about 73 to 78 %, depending on energy sources. The use of circular practices like refurbishment and use of materials recovered from manufacturing waste and recycled materials replacing virgin ones can help further reduce BEVs’ initial footprint, which is typically higher due to battery manufacturing.

In this article, we’ll talk about how organizations can use circular economy principles to their advantage, and what key considerations they need to make when looking to reduce resource use, reduce the carbon footprint of fleets, meet ESG targets, and reduce costs.

How a circular approach to fleet management can help reduce waste and extend fleet life

Opting for a used vehicle creates emissions avoidance, by postponing the manufacturing of a new one. How do you achieve this? Through informed procurement choices, proactive servicing, and refurbishment.

Ensure the rightsizing of fleets and vehicles

The first step in applying circular economy principles to fleet management is adapting fleets to actual needs, i.e. procuring vehicles only when they are truly needed and ensuring they are the right size for users’ needs.

It is essential to ensure, prior to procurement, that every vehicle truly contributes to fleet efficiency, as oversized or idle vehicles represent a waste of resources. Tools such as telematics can also help monitor actual usage and fit for purpose. Additionally, implementing mobility policies is key to offering alternative solutions for employees with low utilization rates.

Prioritize modular design whenever possible

When selecting vehicles, you may verify that the OEMs offer original parts and/or reconditioned parts, that technical manuals are accessible to all repairers, including independent ones, but also that there are no software locks or component pairing systems. They also enable targeted upgrades without having to replace the entire vehicle or subsystem, extending the lifespan of each unit.

Renault Trucks, for example, offers modular batteries (between 3–6 packs depending on range needs), wheelbases, and standardized drivetrain components across its E-Tech line. This enables fleet operators to define vehicle specs with precision, and remain flexible whenever an upgrade is needed, or even swap batteries and components between vehicles.

Stellantis introduced in 2022 their umbrella brand SUSTAINera to better highlight their circular economy initiatives. The company applies the 4R strategy: reman (remanufacturing), repair, reuse, and recycling.

Invest in proactive maintenance

Next, you need to make sure you’re maintaining your fleet proactively.

Seasoned fleet managers are deeply familiar with the concept of predictive maintenance, but telematics and AI diagnostics make this easier to handle. This extends the useful life of both the vehicle and its components – which could then be reused – and reduces disruptions and downtime.

Plus, battery electric vehicles require less maintenance than ICE vehicles overall, which further simplifies operations. Studies show that within the first 50,000 miles, BEV maintenance and repair costs were 57% lower than ICE vehicles.

Refurbish vehicles – and use refurbished parts

Instead of selling older vehicles, you can consider certified refurbishment programs or internal reallocation as well as used car leasing, all solutions preventing the manufacture of a brand-new vehicle and its draw on finite resource.

Some OEMs now offer certified refurbishment programs that support circular economy goals without reducing performance.

Heavy-duty vehicle manufacturer Caterpillar has been remanufacturing components since 1973 through its Cat Reman initiative. Worn engines, hydraulics, transmissions, and other parts are returned to authorized dealers, disassembled, cleaned, repaired, and sold back with full warranty at lower cost.

And, as far as reallocation is concerned, you could reassign vehicles based on needs and capacity. For example, a light commercial vehicle (LCV) that’s no longer suited for urban deliveries could be reassigned to light-duty tasks like on-site transport.

Additionally, you could use reconditioned parts whenever possible, such as electronics, optics, body parts, or battery components – for both ICE vehicles and BEVs, refurbished parts can be very reliable while delivering significant cost savings, often up to 50%. And, obviously, they have a lower environmental impact.

Plan for battery longevity and second life

While vehicle batteries lose some capacity over time, this doesn’t mean they can no longer be useful. In fact, modern EV batteries lose just 1.8% of their capacity per year, meaning they can retain more than 80% of their state of health (SOH) after 12 years. Second-life applications should be deployed, such as repurposing degraded batteries for stationary energy storage in depots or buildings.

Additionally, choosing vehicles with modular or swappable battery packs also makes it easier to manage degradation and reuse cells efficiently.

Source tyres from the right suppliers

Tyres are among the most frequently replaced components in a fleet. Thankfully, retreading programs can now give tyres a second (or even third) life, reducing waste, costs, and the use of natural resources. Indeed, a tire can be reused if its structure is intact and meets safety standards; if not, it should be recycled through authorized channels, prioritizing material recovery over disposal, in line with circular economy principles.

To mitigate the environmental impact and lower costs, you can partner with suppliers that use sustainably sourced rubber and recycle worn-out tyres to improve the fleet’s environmental footprint.

Vehicle Recycling: Maximizing Material Recovery Beyond Reuse

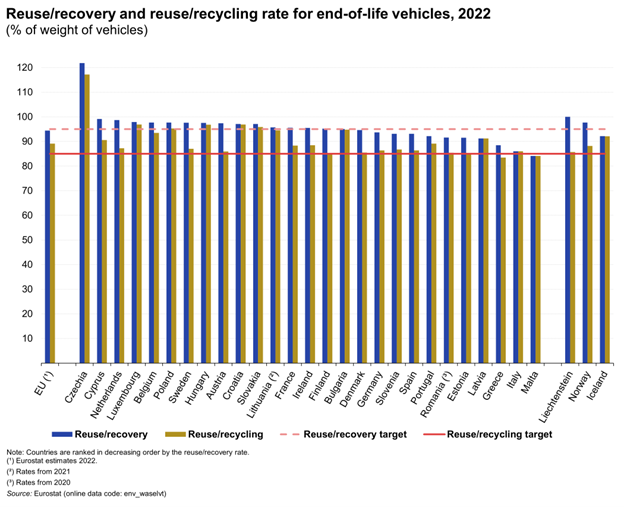

When a vehicle reaches the end of its life span, its materials can, for the most part, be recovered and recycled. This ensures materials are reintroduced into the supply chain, rather than ending up in landfills – and many countries are creating legal frameworks for recycling vehicle parts. In the EU, for example, the End-of-Life Vehicle Directive requires a minimum reuse and recovery rate of 95% by a vehicle’s weight, and of 85% for reuse and recycling. The good news? In 2022, 89.1% of end-of-life vehicles in the EU were reused or recycled.

Reuse/recovery and reuse/recycling rates for vehicles’ end of life in the EU in 2022, by % of weight (Source: Eurostat)

Batteries hold approximately 40% of the value of battery-electric vehicles (BEVs) and their recycling is key for reducing the environmental impact of fleets. Batteries contain critical materials like lithium, cobalt, and nickel, which are both environmentally intensive to mine and crucially important for future battery production. New recycling technologies, like hydrometallurgical and direct cathode recycling, are improving recovery rates.

For your organization to be a proactive participant in this, ensure compliance, and meet its ESG targets, you need the right network of partners and authorized treatment facilities (ATFs) to properly dismantle and recycle vehicles and their batteries. Battery take-back partnerships and OEMs that offer closed-loop recycling programs could further help in this direction.

A circular economy approach is key for the full decarbonization of fleets

Fleet electrification is a major step toward decarbonization, but it is not the final one. Circular practices—such as extending vehicle life through repair and refurbishment, reusing components, and recycling batteries—help achieve a more sustainable approach. However, sustainability requires examining every stage of a vehicle’s lifespan. This includes allocation to employees, catalog selection, procurement and maintenance, as well as reuse, reallocation, and recycling.

Advances in predictive maintenance, battery recycling technology, and digital traceability progressively make it easier to embed circular practices into fleet operations. For this, fleet managers need to:

- Analyze users’ effective needs

- Rightsize vehicles to their specific use and purpose

- Prioritize long-life vehicles that can be repaired easily, ideally with modular components

- Use proactive maintenance to reduce breakdowns and downtime

- Partner with suppliers who offer refurbishment and recycling programs

- Anticipate the end of life of batteries and reuse or recycle them as appropriate

There isn’t a one-size-fits-all solution – you need to carefully consider your needs and objectives. However, by adopting a circular approach to fleet management now, you’ll be better prepared to meet long-term sustainability challenges without compromising vehicle performance and availability.