Traduction en français en cours

Arval is committed to reduce CO2 emissions to bring a more sustainable mobility in the future, where the performance of electric vehicles (EVs) under towing conditions is necessary in terms of efficiency and range, particularly for commercial activities. Therefore, the Arval Consulting published a dedicated study, addressing this knowledge gap by conducting comprehensive tests on a range of vehicle types.

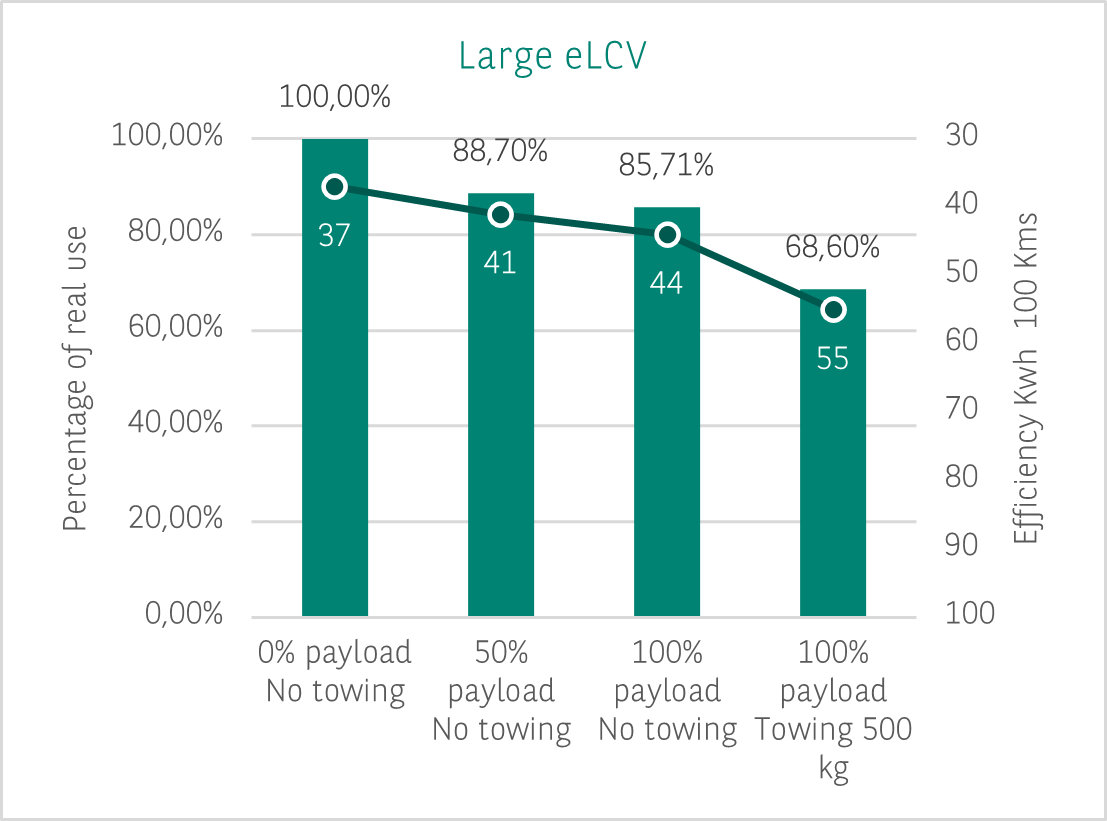

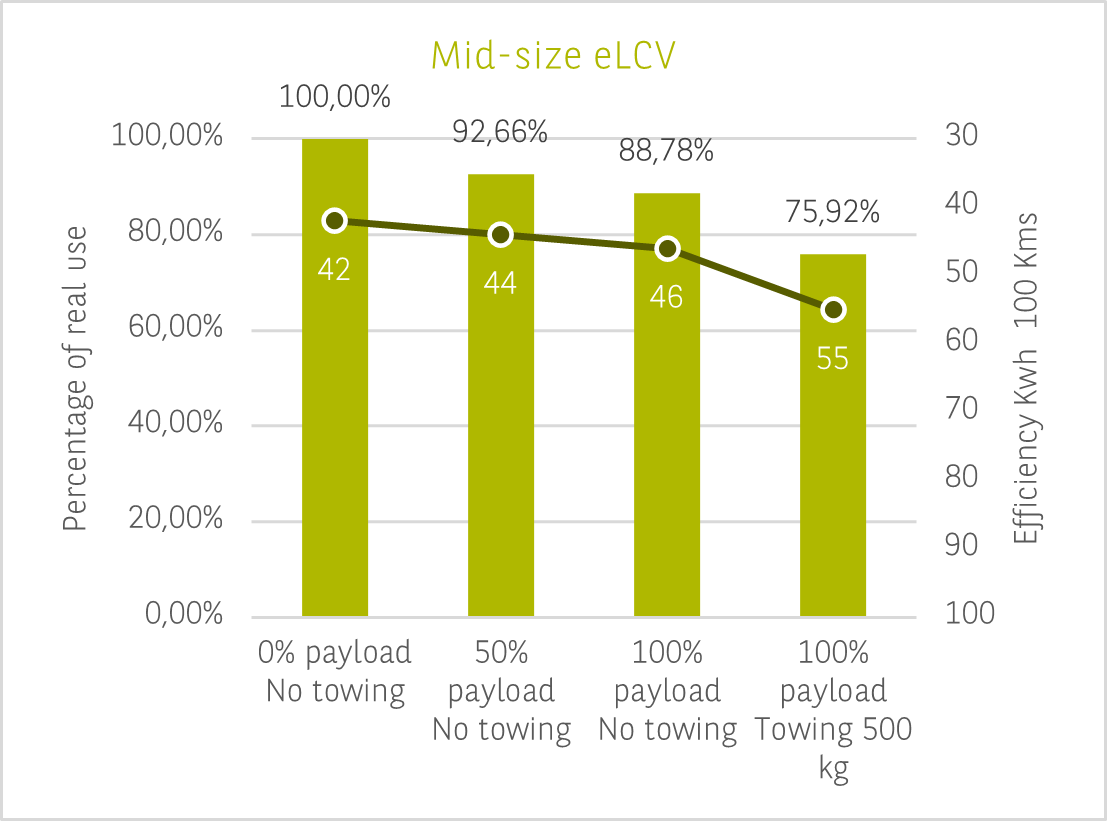

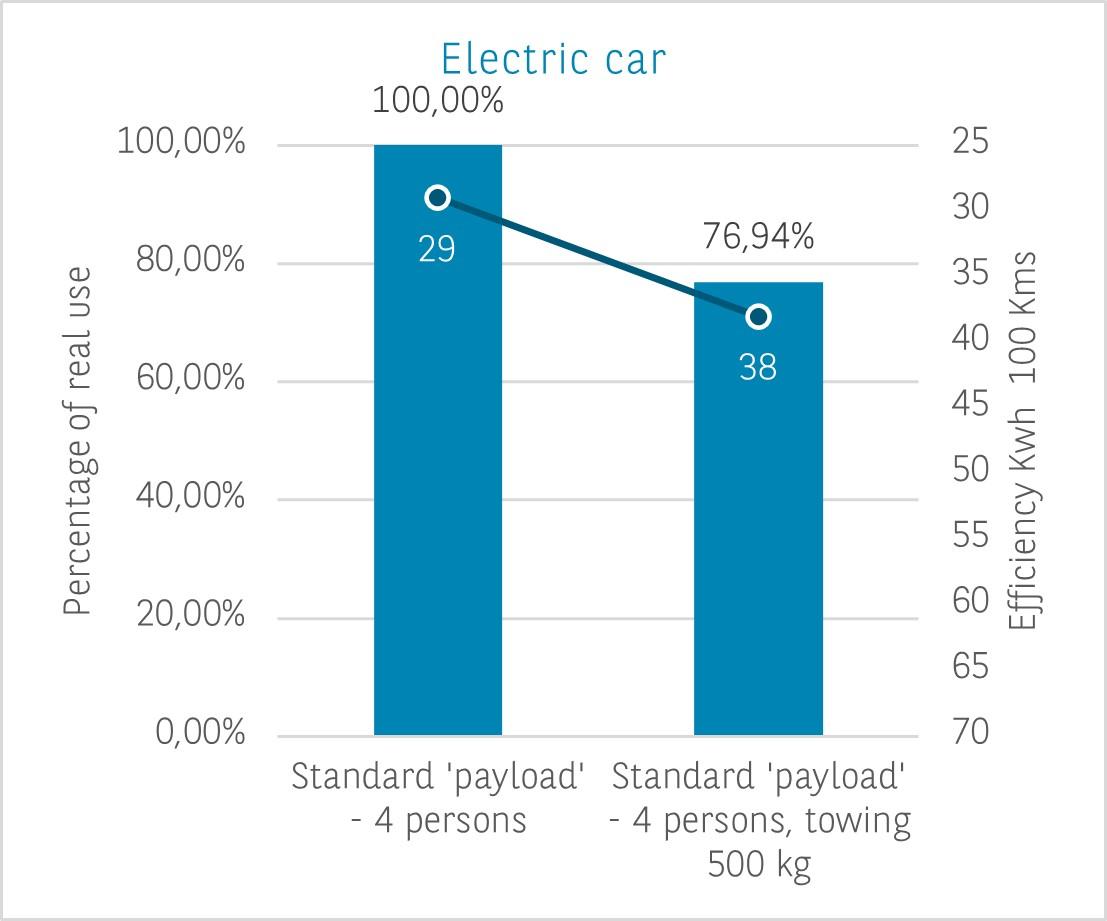

Recent tests were carried out by Arval and The United Test and Assembly Centre (UTAC), world-renowned and specialized in vehicle testing and approval, at its test centre in Millbrook, Bedfordshire UK. Results revealed that a full payload and 500kg towing reduces a battery electric car’s range to 76,94% of its real-world range. It’s practically the same result for mid-size eLCVs for which the impact of such towing and payload reduced the real-use at 75.92%. The most severe impact, touch the large eLCVs where the real-use percentage is only 68,60% with a full payload and 500kg towing situation.

In this article, we will delve deeper into these findings, exploring the methodology used to obtain said data for each vehicle type (large and mid-size e-LCVs and electric cars), the results analysis, and the main implications for fleet operators considering the adoption of EVs for payload and towing purposes.

Methodology: Evaluating the Real-Use Range of Electric Vehicles and the impact of temperatures

The study demonstrated that the real-world range of electric vehicles (eLCVs and cars) is significantly lower than their official WLTP figures: Data shows that full-size electric LCVs achieve just 57% of their WLTP range, mid-size LCVs 55%, and electric cars 50%.

Vehicles were pre-conditioned at 23°C, warmed up, fully charged, and tested over 80 km with headlights on and tires at recommended pressures. Four scenarios were tested for eLCVs: 0%, 50%, and 100% payloads without towing, and 100% payload with towing 500kg. For cars, two scenarios were tested: four passengers without towing and with towing 500 kg.

Building on Arval’s 2021 ‘Electric Fleet Transition Powered by Real-World Data’ report, the first independent investigation into the impact of temperature and payload on electric LCV real-use range, the current study further emphasizes these findings. The 2021 report showed that lower ambient temperatures, typically found in a northwest Europe winter, can more than halve an eLCV’s official range, though typically reduce it to around 72% of the official figure.

While payload affects range, its impact is less drastic than cold weather, averaging an 8% reduction. Combined, cold weather and a full payload put together provide a critical baseline for e-LCV operators, as they can reduce range to almost 50% of the WLTP figure.

Test results: Towing markedly decreases the range of e-LCVs and electric vehicles

The study demonstrated notable decreases in the range of vehicles under various load and towing conditions. For large eLCVs, transitioning from unladen to half load caused an 11.3 percentage point drop in range, with an additional 3 percentage point reduction at full load. Towing with a full load further reduced the range by 17 percentage points, culminating in a total decrease of 31.4 percentage points, leaving the vehicle with 68.6% of its real-use maximum range.

Mid-size eLCVs showed a 7.3 percentage point drop in range from unladen to 50% load, followed by a further 3.9 percentage point reduction at full load. Towing with a full load led to an additional 12.9 percentage point drop, resulting in a total reduction of 24.1 percentage points and leaving the vehicle with 75.9% of its real-use maximum range.

For electric cars, towing caused a 23.1 percentage point reduction in range, resulting in 76.9% of the real-use figure when towing the maximum load.

Towing capabilities: Evaluating the efficiency of Electric Vehicles

Data above reveals the substantial impact of towing on battery electric vehicles (BEVs). For large commercial vehicle, towing while carrying a full load can reduce range by 25%-33% compared to real-use figures, significantly more than the 15% efficiency drop seen in diesel vans under similar conditions. The tested electric car experienced a 23% point drop in range, reducing its real-use distance from 240 km to 185 km when towing.

Furthermore, BEVs face additional hurdles due to their shorter initial range and longer recharging times, complicating the transition for businesses accustomed to diesel fleets. For example, a mid-size electric van may tow 750 kg, whereas a similar diesel van could tow up to 3000 kg. Despite this, BEVs offer better torque and stability for towing, and future electric LCVs are expected to have higher towing capacities.

Still, the critical challenge of shorter range and longer refueling times of BEVs remains, especially for businesses accustomed to the longer range and quick replenishing of diesel vehicles.

Charging infrastructure: a significant barrier to BEV adoption for towing

Effective and convenient recharging solutions, particularly at workplaces and homes, are essential. Simplifying and speeding up the recharging process, with ample opportunities for charging during stationary periods like office hours or depot parking, would alleviate many range-related issues. Unlike diesel vans, which have had accessible refueling points for the past century, the transition to electric vehicles requires ensuring that eLCVs can fulfill their job requirements without concerns.

Arval’s research indicates that drivers appreciate the performance of electric vans, indicating acceptance. However, managing charging downtime, especially for high mileage eLCV operators poses a real challenge. Despite stable plans to install charging points at company premises according to the Arval Mobility Observatory Barometer 2024*, the design and availability of charging points need improvement, as most do not accommodate larger LCVs efficiently.

Workplace or home charging becomes crucial for fleets operating eLCVs, aiming for vehicles capable of completing a day’s work on a single charge. Yet, larger depot-based fleets face challenges regarding infrastructure upgrades and downtime implications, which can impact industries with time-sensitive goods or high-value personnel.

Clear, accurate information is critical to reach a solution for BEV adoption

In conclusion, future solutions and the path forward transitioning to electric vehicles remains feasible with precise data and advancements in technology and infrastructure. Businesses must carefully consider these factors to make informed decisions and avoid costly errors. Addressing these challenges is imperative to fully realize the benefits of BEVs in commercial operations. In the early stages of BEV adoption, accurate and detailed information is crucial.

Comprehensive research, such as this provided by Arval and UTAC, allows fleets to assess how they can adopt electric vehicles without significant changes to their business models. The journey to electrification is complex but achievable with the right data and planning.

As for potential solutions, increasing the number of vehicles, expanding charging locations, adopting a hub-and-spoke distribution model, and enhancing business charging infrastructure can ultimately be a game changer for fleet operators. For instance, the Arval Energy** initiative set in place by Arval aims to provide more accessibility to charging stations. Electric vehicles of all types, eLCVs in this case, can potentially benefit down the line from faster and more intelligent energy recharging, through Smart Charging and V1G, as well as the future bidirectional charging or Vehicle2grid (V2G).

For more details about Arval and UTAC’s research, check out the full study of Arval Consulting here.

*For the latest results of the Arval Mobility Observatory 2024, follow the link: The Arval Mobility Observatory Fleet and Mobility Barometer 2024

**To know more about Arval Energy: Arval launches Arval Energy, a strategic initiative unlocking the full potential of smart charging for electric vehicles